Print current page

Print current pageProduct Description

- brief introduction

- technical parameter

- Product size

Application

The high voltage shunt capacitor compensating device is mainly used in 6-10KV three phases system, to adjust and balance the network

voltage, improve power factor, lessen loss and improve the electric quality.

This device meet with standard of JB7112-2000 "Aggregate High voltage shunt capacitor" andDL/T628-1997 "technical rules on ordering for

Aggregate High voltage shunt capacitor", GB50277-1995 "Technical design regulationsfor shunt capacitor switchgear".

Working conditions

Altitude of mounting site: not more than 1000m.

Mounting size shall have no severe vibration, no corrosive gas and steam, no conductive and explosivedust Ambient temperature.

Indoor use: 5℃ ~ 40℃; outdoor use 40℃~ 40℃.

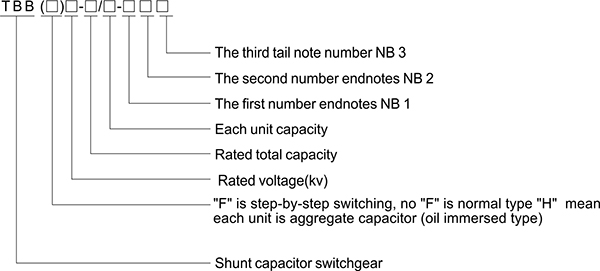

Model and implication

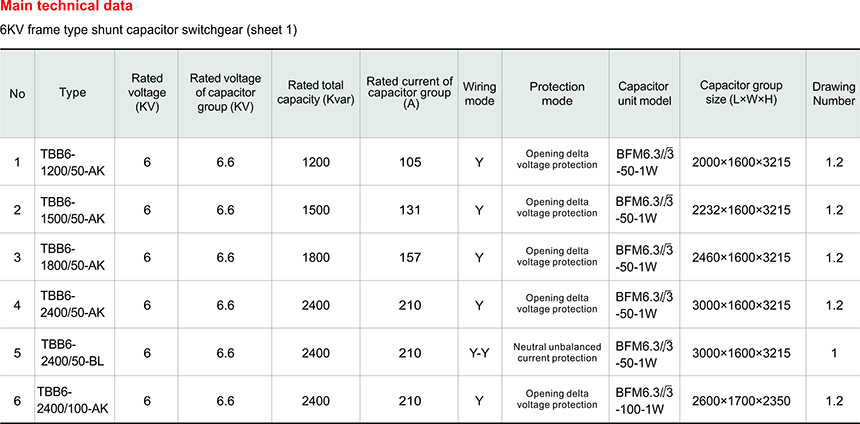

Main technical specifications

The switchgear can work long-term under 1.1 Un.

The switchgear can work long-term under 1.3 In rms rated current of capacitor group, which over current is generally come from harmonic wave and

1.1Un action.

Under above clause 4.1 and 4.2 action, the total capacity shall not more than 1.35 rated total capacity.

The deviation between the measured capacitance and the rated capacitance shall be within 0-+10%, when the deviation reach up to 10%, the over current mentioned in clause 4.2 can reach up to 1.43.

The over-current resulted from power frequency and harmonic wave voltage shall not more than the value specified in clause 4.2. when the switchgear work under 1.1 Un and below for long term, the peak voltage value including all harmonic values shall not more than 1.22Un.

The switchgear connected with no-severe break-down circuit breaker and ZnO arrester to limit the operational over voltage. 6KV, 10KV capacitor switchgear use vacuum load switch, VCB or SF6 breaker as the switch. Regarding the small capacity switchgear, and where it need step-by-step switch the capacitor group, we recommend to use vacuum load switch, regarding the large capacity switchgear, it shall use VCB or SF6 breaker.

CKGK dry type hollow resistor connected to power source side or CKSW oil immersed steel core resistor connected to neutral line is used to limit surge during close operation, finally to restrain the hi-freq harmonic wave, improve voltage wave. Rated resistive rate 0.5~1% resistor is used to restrain surge coming from closing operation, rate 5-6% resistor is used to restrain 2times frequency wave and surge coming from closing operation, rate 12-13% resistor is used to restrain 3 times frequency wave and surge coming from closing operation.

FD discharge coil is used, it can discharge the electricity and let the residual voltage come down to 0.1 time rated voltage within 5s.

As required, local control, main control room, central control or automatic control can be provided.

Main protection is that each capacitor unit has fuse, (aggregate oil immersed capacitor bank is mainly protected by inner fuse), opening delta overvoltage protection, voltage differential protection, neutral unbalanced current protection are as backup protection modes, moreover, over-current protection, quick-break, over-voltage protection, voltage failure protection are provided,

Step-by-step switching capacitor switchgear is according to different capacity, divide several groups (1~3), and provided with multi-functional auto-controller, in the command of voltage status and reactive capacity to control the vacuum load switch or breaker switching on/off reasonably.

Structure

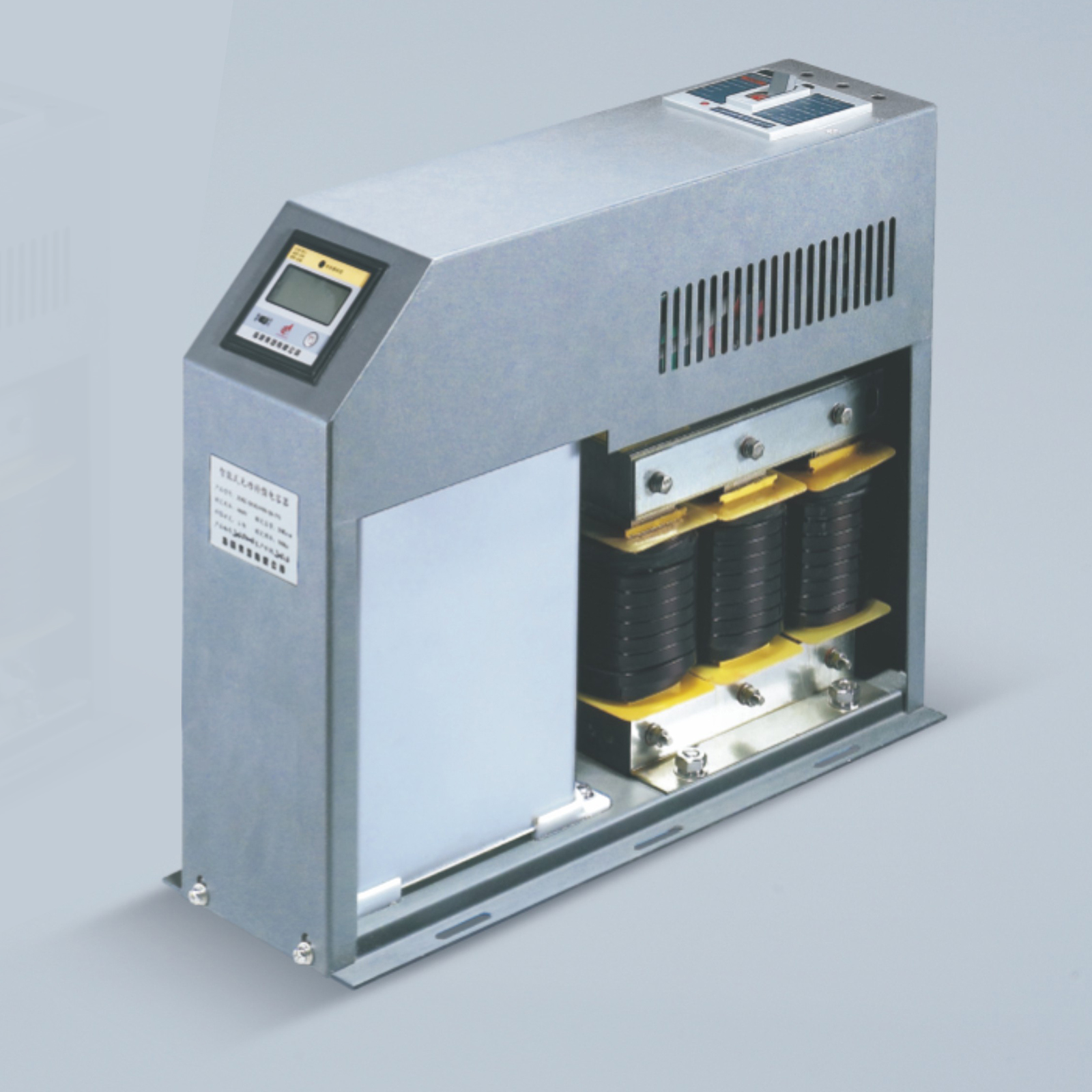

6-10KV capacitor switchgear consist of HV switchgear (breaker, isolator, CT, relay protection, metering system), series connected resistor, discharging coil,

ZnO arrester, earth switch, fuses for each capacitor unit, shunt capacitor units, busbar and steel mounting supports. Y-Y type also includes CT for neutral unbalanced current protection.

According to shunt capacitor and structure, divided: Frame type, Split type, indoor panel type, aggregate type.

Frame type

Capacitor group includes incoming support and capacitor supports, the whole switchgear divided into several parts, and transported to the site for mounting, incoming support fixed with discharging coil, earth switch, ZnO arrester, if Y-Y type, there CT for neutral unbalanced current protection is fixed as well, and capacitor support includes fuses, busbars.

Split type

The difference from the frame type is that this is constructed as discharging coil panel, capacitor panel, it is enough that combine them together on site.

The whole switchgear provides mechanical and electrical interlocks.

Indoor panel type.

Capacitor group according to different capacity form 1 incoming panel and 1 or several capacitor panels, incoming panel consists of discharging coil, earth switch, ZnO arrester, capacitor panel includes capacitor, fuse for each capacitor units.

Aggregate type: this type consists of aggregate (oil immersed) capacitor, and discharging coil, ZnO arrester, resistor, earth switch, the discharging coil is mounted upon the capacitor or resistor supports. The switchgear capacity depends on the aggregate capacitors.

Wiring of series connected resistor.

The resistor has three kinds: dry hollow type series resistor, dry three phases series resistor and oil immersed resistor. According to wiring layout, the resistor can be connected in front of or back of capacitor group, namely besides power source side or neutral line.

The mounting dimensions in sheet are only for reference.

中文

中文 ENGLISH

ENGLISH Email:

Email: website:

website: Service hotline

Service hotline